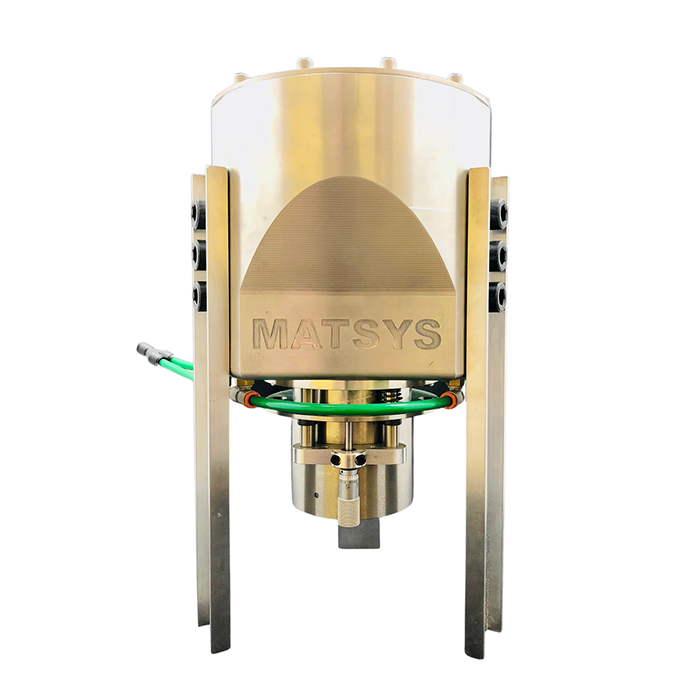

Powder Valve

The MATSYS Powder Valve offers a fully customizable solution for improved powder flow. Using dry gas, the valve increases flow consistency and reduces interparticle friction, resulting in tailorable dispensing rates and output control, applicable to a broad range of materials.

The Powder Valve uses a dry gas, such as air, nitrogen, or argon, to coat particles and separate them, reducing interparticle friction and providing a transport mechanism, avoiding the need for bulk lubricants traditionally used in powder blending. The friction reduction overcomes the locking effect of powder within the confined opening between the Funnel and the Stop Valve, facilitating greater control over the way the powder flows.

The Valve contains no moving parts, eliminates mechanical shearing, and sets the new standard for powder handling with improved flow versus traditional valve types. This patented powder flow control valve was originally designed for dispensing poorly-flowing, high-density powder for our in-house manufacturing processes. It has been optimized for use with a broad range of particulate materials.

MATSYS can supply these valves in various sizes ranging from a small, hand-held filler (cubic centimeters per second) to a large, production scale dispenser (liters per second). A pulsed dosing option, as well as a load-cell feedback option, are both available for accurate flow rate and measured weight output dispensing.

Custom Powder Flow Devices & Processes

Our unique powder handling and consolidation expertise allows us to produce custom powder flow devices and processes that improve powder flow consistency and density at variable rates across your entire powder catalog, including hard-to-flow powders.