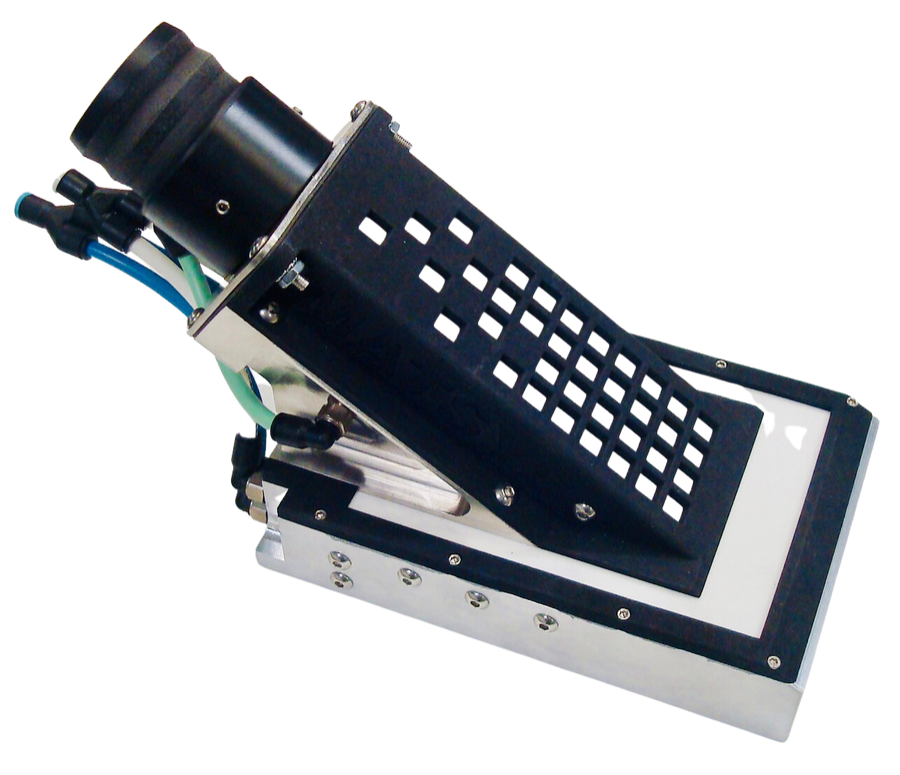

Fluidized Fill Shoe

The MATSYS Fluidized Fill Shoe System is a powder delivery system designed to mitigate common flow problems in gravity-fed systems, resulting in reduced friction and consistent and efficient filling of small die cavities. The Fill Shoe System is proven to achieve greater density uniformity and throughput.

The Fill Shoe System consists of a fluidized fill shoe and control cabinet and is fully customizable. Independent gas chambers fluidize the particulate material, allowing the powder to flow like a fluid as it is supported by a column of gas. The result is a reduction in the effects of head pressure, clumping, and surge. The Fluidized Fill Shoe creates a low-pressure gas bearing below the powder inside the shoe to reduce the friction along the powder path to the fill point. By flowing gas through a bed of solid particles from the bottom to the top, the bed is loosened and fluidized, and particles are easier to move.

Custom Powder Flow Devices & Processes

Our unique powder handling and consolidation expertise allows us to produce custom powder flow devices and processes that improve powder flow consistency and density at variable rates across your entire powder catalog, including hard-to-flow powders.