CUSTOM POWDER FLOW DEVICES & PROCESSING

Improve Flow Consistency & Density Across Your Entire Powder Catalog

OUR CUSTOM POWDER DEVICE & PROCESSING SERVICES

Decades of expertise in powder handling and consolidation led us to engineer & produce devices and technologies that enable consistency and control of powder flow. Our fluidization technology significantly improves conveying operations of powders with poor flowability.

FLUIDIZATION TECHNOLOGY

MATSYS is a world-leader in the development and application of fluidization techniques to facilitate and control the flow of powders. Our proprietary technology relies on the use of dry gas at low pressure to lubricate powders at the particle level, reducing inter-particle friction and enabling gravitational flow. Our designs eliminate the need for solid lubricants, improve powder flow consistency, and increase powder flow rates.

Our work with customers across industries has allowed us to apply our fluidization technology to diverse problems related to powder flow—from hoppers, powder valves, and fill shoes for the press and sinter industry to a wide range of custom needs for our ever-growing customer base. These devices have been used in applications ranging from low-density polymers and ceramics and metal powders of non-uniform morphology to battery production operations and cohesive excipients of the pharmaceutical industry. MATSYS fluidized devices can be easily tailored to enable the precise control of powder flow at the milligram scale or the dispensing of multi-kilogram quantities of powders per minute.

WHY OUR FLUIDIZATION SYSTEMS?

Improved powder flow

No impact on powder morphology

Ideal for remote operations

Scalable technology

Low wear and maintenance

Flexible product line

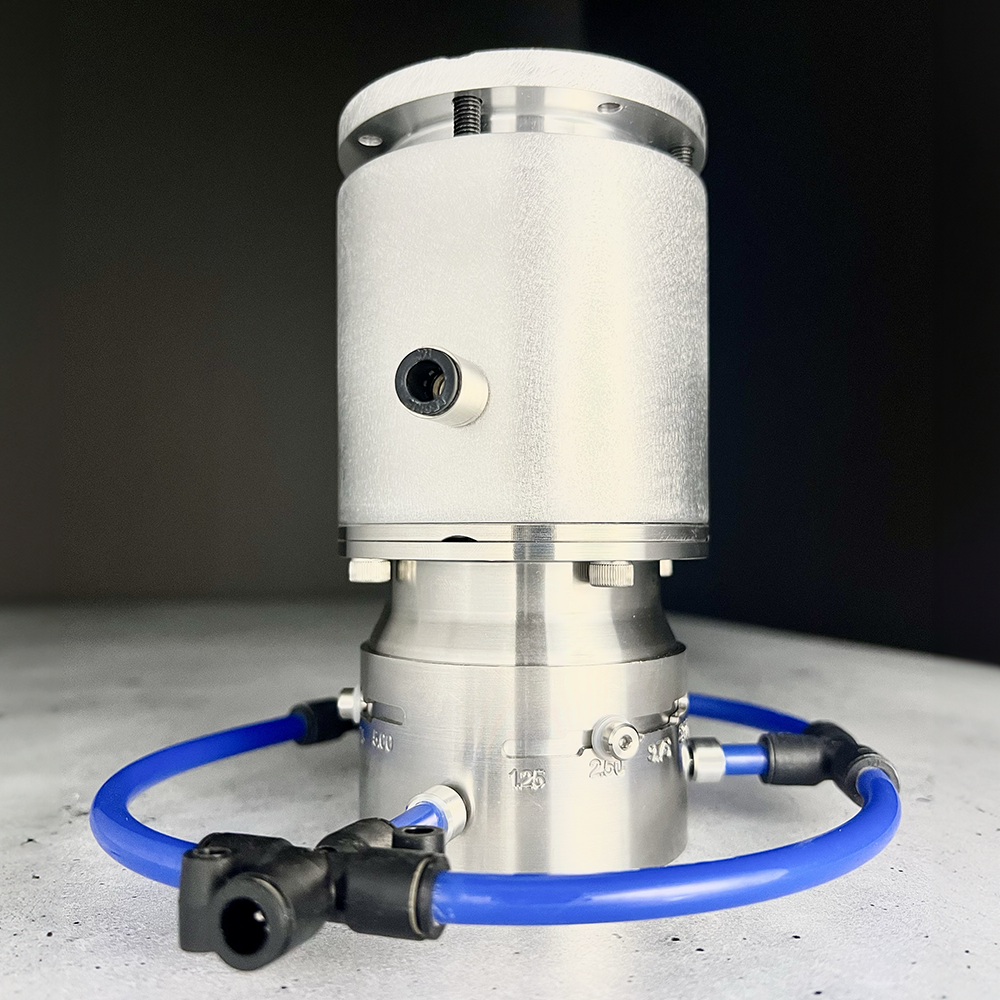

(In-Line) Valves

Conduits

Tubes/Pipes

Hoppers

Flow Meters

HOW IT WORKS

The use of fluidization in powder flow technologies decreases interparticle friction, promoting a consistent and uniform powder flow, especially in comparison to gravity-fed systems.

Dry gas acts as a lubricant for the powder, ensuring a steady flow through the system. This method is particularly beneficial for powders with irregular shapes, high cohesion, poor flow properties, and sensitivity to shear and friction (such as energetic materials and sensitive polymorphs).

Since the powder flow is not mechanically regulated, our system operates without moving parts, significantly reducing maintenance requirements and elongating its lifespan.

The absence of moving components also safeguards against unintended alterations in powder particle morphology.

A SOLUTION FOR EVERY PROBLEM

Our system is modular and customizable to your unique needs. Our technology can be retrofitted into existing equipment for rapid and effective remediation of your powder flow problem.